Electric Floor Heating System for Floating Floors

- Used with most floating laminate, engineered wood, floating tile floors, Snapstone floating tile floors & luxury vinyl planks and tiles 4mm or thicker

- Uses an highly-efficient conductive ink technology

- Disperses an evenly consistent heat throughout the entire floor

- Will not add extra height to the floor, less than the thickness of a credit card

- Consumes up to 50% less power than traditional wired systems

- Easy to install: roll out, cut length to fit if needed and run pre-attached wires to a wall thermostat

- No mortar and no mess

- Conforms to many floating floor manufacturers requirements

- Maintenance free, crafted to not completely shut down if the system should ever become compromised or damaged

- Includes 15 feet of factory attached leads

- Adjust temperature with QuietWarmth Thermostat (Sold Separately)

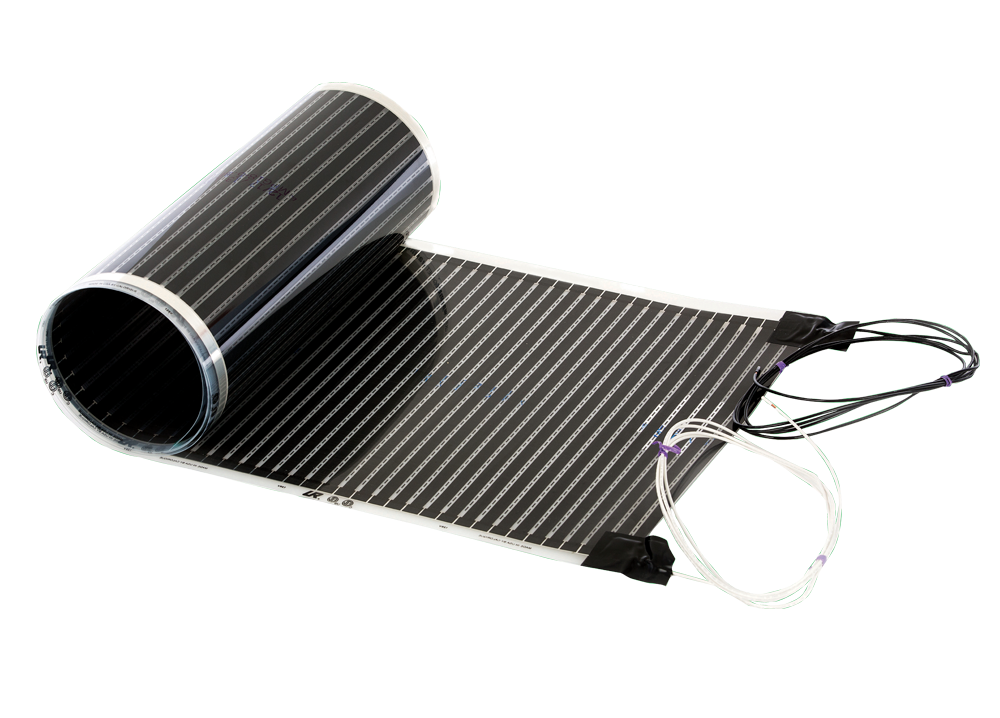

This system is a gentle electric radiant heat system designed specifically for dry installation under floating wood and laminate floors. As a low profile, line voltage system, it allows for gradual warmth from the low wattage resistance heating made of an ultra-thin, flexible radiant heat film. The system installs easily over a subfloor or over an acoustic/insulating underlayment as part of the overall floor assembly. It also uses just 12 watts per square foot to gently raise the temperature of the floor, abiding to the warranty requirements of many floating floors. This system, which sports an impressive efficiency rate of 99%, includes temperature limiting properties so the film does not overheat. It’s available in four convenient rollout mat sizes that will accommodate most layouts and each mat has wires pre-attached for easy installation.

Installation Instructions

The QuietWarmth Radiant Heat Film mats are thin and flexible - thinner than a credit card. This makes the system less expensive and easy to install without needing any extra mortar or backer boards.

Works well over the top of QuietWalk underlayment. Excellent R-Value and provides a great thermal break to the subfloor to help push the heat upwards to warm the floor.

Step 1: Roll out film

Step 2: Cut to length and route lead connections

Step 3: Same day flooring installation

Because of the parallel architecture of the system, the mat can be cut to fit lengthwise without compromising the system's flow of electricity to each stripe. Be careful, as you cannot cut the system to width as that will destroy the parallel architecture of the mats.